“It is counterproductive to define Industry 4.0 through the technologies that make it possible. It is much more useful to define it in terms of the practical benefit it delivers.”

Industry 4.0 is a subject that is much hyped these days. Governments are financially encouraging their manufacturing industries to develop Industry 4.0 programs. Business strategists, such as McKinsey and Deloitte, publish a constant stream of articles on its value and importance. And the fact that most definitions of Industry 4.0 are based on other hyper-sexy topics such as AI, IoT, Cloud, Additive Manufacturing and 5G only further bolsters its significance.

But down at ground level, many people who run manufacturing businesses frequently don’t understand what Industry 4.0 is about. Too often, I’ve heard Industry 4.0 referred to as “meaningless container terminology” because it is usually defined through technologies that make it possible. This is counterproductive and alienates the very people that Industry 4.0 needs to target: the owners of manufacturing business challenges. This audience doesn’t think from a technology perspective. It doesn’t think, “if I had AI, what could I do with it?”. It thinks in terms of either “how can I make more widgets in less time, with less waste and less cost” or “how can I better meet the needs of my customers”, or both.

I was recently introduced to a company whom I was told wanted to integrate the machines they manufacture into an IoT platform. Upon meeting them I carefully listened to their ideas for this platform, which essentially focused on “how”. They had extensive ideas about adding sensors, collecting data and dumping it into the cloud. Ultimately, quite expensive ideas.

When I asked them about the “why” behind their ideas, they more or less dried up. They hadn’t thought about the value they hoped to create with their IoT platform, nor how to monetize it. They hadn’t thought about how to take the idea to market, how their customers might react. They hadn’t stood in the shoes of their customers and considered what they need. More or less their motivation was based on the dazzling promise of exciting technology. And when one stands back and looks at the definition of Industry 4.0, one cannot blame them as the whole thing centers on “how”. This is strange, really, as any Industry 4.0 program that is not deeply grounded in “why”, is doomed to failure.

For the owners of manufacturing business challenges, it is much more meaningful to define Industry 4.0 in terms of the practical benefits that it delivers. Getting back to basics, Industry 4.0 is relevant to a business to the extent that it enables that business to create more value. In other words, Industry 4.0 is a means to and end and not an end in itself, that end being defined by the vision and mission of a business. The true power of Industry 4.0 is its ability to deliver better efficiency, flexibility, sustainability, customer value and financial performance. In each of these areas, Industry 4.0 provides rich possibilities for value creation. The technology of Industry 4.0 is – indeed – a means to this end.

There’s one caveat to this line of reasoning. Industry 4.0 technology makes possible things that a business might not have considered when framing its mission. Therefore, understanding the possibilities of Industry 4.0 technology can provide business owners with new insights in how to realize their business goals.

So, what is Industry 4.0? Fundamentally, is a collection of technologies that, when applied to a manufacturing business, enable a leap in the performance and value creation capability of that business.

Read also

An outbreak of hubris

Software is the medium of digitalisation. If you don’t understand software, you have no hope of coming up with a decent digitalisation strategy.

Software is not a component of a vehicle

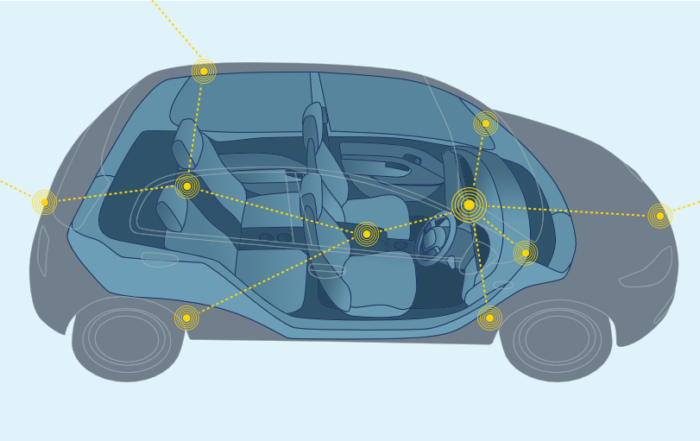

Automotive OEMs have evolved to become highly efficient outsourcing and system integration organizations. Everything related to a vehicle is thought of as a component, including software. The whole automotive system engineering process treats software as a component of a vehicle. This prevents them thinking about the software as a whole system.

Abstraction versus Vagueness in Software Engineering

Some software engineering teams have a problem understanding the difference between abstraction and vagueness. Since one is essential to the architecture and design of complex systems and the other leads to technical debt and poor software quality, software teams must grok the difference.