The full economic consequences of the coronavirus pandemic are far from being understood, but it is already clear that there will be lasting if not permanent changes to global trade. Industrial Digitalisation will play a key role in helping manufacturing companies survive the coming turmoil.

The key to benefitting from 4IR is committed leadership and management action. In comparison to establishing this, implementing industrial digitalisation is relatively straight forward. Experience shows that many manufacturing businesses have bottlenecks that can be quickly solved by a small dose of digitalisation. Quick wins are often possible in a three month timeframe. Such short term success breeds enthusiasm within an organisation to tackle the next bottleneck and leads to a pragmatic and efficient growth of digitalisation. Frequently the biggest bottleneck to industrial digitalisation is getting started. The differentiating factor between companies who are successful and those who are not (yet) is committed leadership from the top.

Another angle to consider is that the pandemic will result in a shake-up of markets on a scale that dwarfs that of the 2008 economic crash. Weak businesses will lose to the strong, slow businesses to the smart. In the resultant shark-fest, speed, agility and the ability to efficiently deploy resources will differentiate winners from losers. There will be no time to make decisions based on internally developed evidence. Leadership during this crisis is about making judgement calls based on experience and belief. There is enough general evidence of the benefits of industrial digitalisation for business leaders to believe in it and commit to it, particularly in the light of the current crisis.

That businesses now face exceptional challenges is a given fact and exceptional measures will be required before a new economic equilibrium is reached. For industrial companies, digitalisation represents a sure way to create a leaner, more efficient organisation capable of quickly responding to or driving changes in the market. Investing in 4IR is a sure way not to waste a good crisis.

Read also

An outbreak of hubris

Software is the medium of digitalisation. If you don’t understand software, you have no hope of coming up with a decent digitalisation strategy.

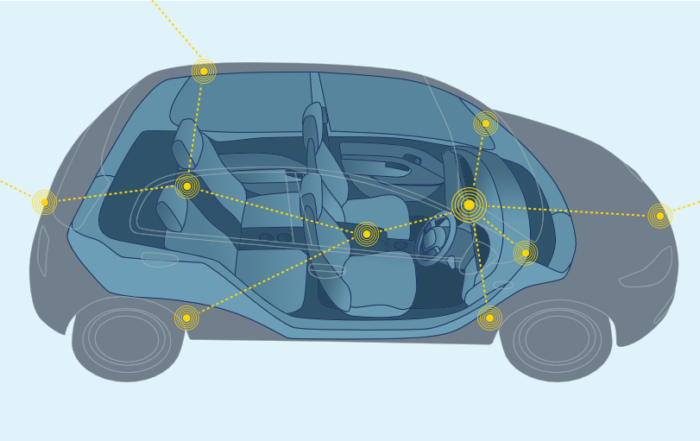

Software is not a component of a vehicle

Automotive OEMs have evolved to become highly efficient outsourcing and system integration organizations. Everything related to a vehicle is thought of as a component, including software. The whole automotive system engineering process treats software as a component of a vehicle. This prevents them thinking about the software as a whole system.

Abstraction versus Vagueness in Software Engineering

Some software engineering teams have a problem understanding the difference between abstraction and vagueness. Since one is essential to the architecture and design of complex systems and the other leads to technical debt and poor software quality, software teams must grok the difference.